#steel production

Explore tagged Tumblr posts

Text

Maraging steel

#maraging#metallurgy#wikipedia#wikipedia pictures#fire#hot#steel#steel products#steel production#maraging steels#steels

98 notes

·

View notes

Text

"Importantly, the team says this technique doesn’t add major costs to either concrete or steel production, and significantly reduces CO2 emissions compared to the usual methods of making both."

8 notes

·

View notes

Text

Spectrometer for Steel Foundries: Enhancing Metal Analysis Efficiency

Steel foundries rely on precise chemical composition analysis to ensure the quality and consistency of their products. A spectrometer for steel foundries plays a pivotal role in achieving this accuracy. It is an essential tool for analyzing metals and alloys, ensuring compliance with industry standards and customer specifications.

Why Steel Foundries Need Spectrometers

Accurate Composition Analysis: Spectrometers provide detailed insights into the chemical composition of steel, helping foundries detect impurities and maintain quality.

Real-Time Results: Advanced spectrometers deliver results quickly, enabling faster decision-making in production processes.

Cost Efficiency: By identifying errors early, spectrometers reduce material waste and rework, optimizing overall production costs.

Key Features of Spectrometers for Steel Foundries

High Sensitivity: Capable of detecting trace elements in metals.

Ease of Use: User-friendly interfaces allow for easy operation and training.

Durability: Built to withstand harsh foundry environments.

Final Word

For steel foundries looking to enhance efficiency, improve product quality, and reduce waste, investing in a reliable spectrometer for steel foundries is a wise decision. Ensure you choose a trusted provider to meet your analytical needs effectively.

By integrating Metal Power's advanced spectrometer solutions into your operations, steel foundries can achieve better control over their processes, stay competitive, and consistently deliver high-quality steel products. Contact Metal Power today to learn how our spectrometers can transform your foundry operations!

#SteelFoundries#metalanalysis#metalpower#steel production#metaltesting#QualityControl#SpectrometerForSteelFoundries

0 notes

Text

Kapila Steel: Excellence in Binding Wire Production

Behind each strong construction project and industrial application stands an unsung hero—the binding wire. This small but crucial part plays an important role in reinforcing the concrete structure, securing various materials, and ensuring integrity in countless construction projects globally.

Understanding Binding Wire: The Foundation of Construction

Binding wire is the intangible bond that holds elements of a construction together. From reinforcement bar tying to fencing materials, this very versatile product has become the indispensable requirement in many sectors. In manufacturing, high attention and commitment to quality are factors that define the production house, Kapila Steel.

The Process of Raw Material to Finished Product

Superior Quality Material is Where Quality Manufacturing Begins

The process of binding wire manufacturing begins with the selection of high-grade steel wire rods. Kapila Steel checks every batch for tensile strength, ductility, and chemical composition. The attention to raw material quality ensures that the final product meets the stringent requirements of modern construction.

Wire Drawing: The Art of Precision

In an advanced wire drawing process, the rods of steel are changed to high-precision diameter wires. Several stages of drawing step by step reduce the wire's diameter while improving the strength and flexibility. Heat treatment and speed in the drawing process are significant aspects in balancing durability and workability.

Heat Treatment: Strengthening the Core

It means an important stage in the binding wire manufacturing process: the process of heat treatment. Specific heating and cooling cycles bring changes in the molecular framework of the wire, setting it to the best optimum of its mechanical properties; the wire remains strong at the same time but may be easily handled on building sites.

Quality Control Methods

Every stage of producing undergoes strict quality checks:

Dimensional exactness test for the appropriate diameter of the wire.

Surface quality checks for uniform finish and integrity of coatings.

Tensile strength tests for strength in stress.

Ductility tests for proper field flexibility.

High-Tech Coating Systems

The wire is coated with special coating depending on the specific need of the application. These may be:

Galvanized coating for high strength against corrosion.

Black annealed coating for easy workability.

PVC coating for some special applications.

The Kapila Steel Difference

Leading Edge Manufacturing Facility

Advanced machinery is housed in the manufacturing facility and calibrated to precise specifications. Automated systems monitor and adjust the production parameters in real-time, ensuring consistent quality in every batch. This technological integration combines with decades of manufacturing expertise to deliver superior binding wire products.

Environmental Responsibility

The production process incorporates sustainable practices, such as:

Energy-efficient manufacturing systems.

Waste reduction initiatives.

Recycling programs for production materials.

Setting Industry Standards

Each lot of binding wire is tested against international quality standards. Third-party verification guarantees the product's compliance with construction industry standards, which provides customers with assurance in its performance and reliability.

Applications and Uses

The Kapila Steel binding wire is versatile and used in various applications:

Reinforcement bar tying in concrete structures.

Fencing and wire mesh manufacturing.

Agricultural applications.

Industrial packaging.

Making the Right Choice

When choosing binding wire for construction projects, several factors are to be considered:

Application requirements.

Environmental exposure conditions.

Tensile strength requirements.

Type of coatings preferred.

Specifications of project.

With attention to all these, project managers will be able to choose the right variant of binding wire for their purpose.

Excellence is Our Promise

Manufacturing at Kapila Steel reflects a sense of understanding construction industry requirements and technical knowledge. Every meter of binding wire will meet stringent requirements for tensile strength, durability, and performance.

Kapila Steel, in fact, displays to all the construction professionals an elaborative process with careful inspection, which means for constructing and building in reliable results with binding wires. These are products manufactured and equipped with comprehensive testing protocols with the latest in advanced techniques for production of the needed products.

Contact Kapila Steel to learn more on how their binding wire may enhance your project and the benefits these have in ensuring that success on completion. Discover what good manufacturing adds in construction outcomes.

#Kapila Steel#binding wire production#high-quality binding wire#steel binding wire#construction materials#reinforcement wire#wire manufacturing#binding wire for construction#reliable binding wire#industrial wire#steel wire products#durable binding wire#binding wire specifications#construction wire solutions#binding wire for concrete#steel wire quality#steel production#binding wire for reinforcement#construction wire industry#binding wire supply#premium quality binding wire.

0 notes

Text

0 notes

Text

Discover the advanced manufacturing processes at Shree TMT that ensure the production of top-tier TMT bars. The company employs state-of-the-art technology and rigorous quality control measures to produce steel that meets the highest industry standards, contributing to safer and more durable infrastructure projects.

#TMT bar manufacturing#steel production#Shree TMT technology#quality control#advanced manufacturing#shreetmt#tmt bars#construction industry#construction materials#construction safety

0 notes

Text

#steel production#enamel sector#Fluorspar#Fluorspar Market#Fluorspar Industry Trends#Fluorspar Market Analysis#Fluorspar Market Forecast

0 notes

Text

The Invisible Fuel: Understanding Coal, Coking Coal, and Their Journey to Steel Plants

Steel, the backbone of modern infrastructure, doesn't magically appear. Its creation relies on a complex dance between raw materials, intricate processes, and efficient logistics. In this intricate ballet, coal, particularly coking coal, plays a vital role. This blog dives into the world of coal, coking coal, and their journey to steel plants. We'll explore the different types of coal, the unique properties of coking coal, and the essential task of coal transfer, ensuring a steady supply for steel production.pen_spark

#Coal Mined#Coal production#Coal Imports#Steel Production#Steel Manufacturing#Steel Capacity#Steel Demand

0 notes

Text

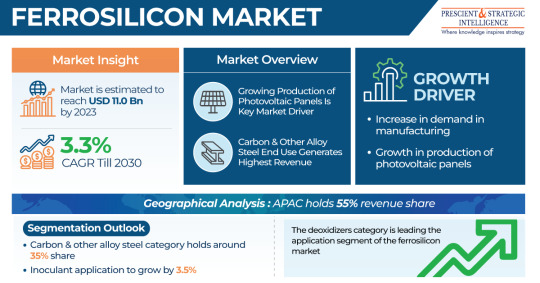

Worldwide Ferrosilicon Market Will Reach USD 13.7 Billion By 2030

The projected revenue of the worldwide ferrosilicon market is around USD 11.0 billion for 2023, with an anticipated increase to USD 13.7 billion by 2030. This growth is forecasted to occur at a compound annual growth rate (CAGR) of 3.3% between 2024 and 2030. This growth of the market can be credited to the extensive variety of applications of this material in the automotive, construction, and…

View On WordPress

#alloy#challenges#environmental considerations#ferrosilicon#global demand#Growth opportunities#industrial applications#market#market trends#metallurgy#pricing dynamics#regulatory landscapes#steel production#Technological advancements

0 notes

Text

Seven Years and Counting!

Photo by Pixabay on Pexels.com December 31st marked our seven years on WordPress and blogging on Lucy’s Written Word. To all my followers, thank you for hanging around with us all these years. I hope you have enjoyed what you have read. Many things have changed in those seven years. I graduated from college, still working for Coffeehouse Writers as a monthly writer contributor and was promoted…

View On WordPress

#celebrating#coal mines#George Magazine#healthcare not the same as health insurance#living the dream#sex trafficking#steel production#Taylor Swift#Ukraine

0 notes

Text

Iron and Steel Market's Journey in Fueling the Engine of Progress

The global iron and steel market size is expected to reach USD 2,253.52 billion by 2030, according to a new report by Grand View Research, Inc. expanding at a CAGR of 3.8% from 2023 to 2030. Rising demand for heavy machinery and growth in the construction industry is expected to augment market growth over the forecast period.

Iron And Steel Market Report Highlights

Based on iron ore application, the steel segment is expected to register a growth rate of 2.0% in terms of revenue over the forecast period. The production of steel is expected to increase over the forecast period on account of rising investments in the construction of smart cities, led by increasing urbanization rates.

For example, Saudi Arabia’s NEOM project is anticipated to consume the largest amount of iron and steel. Further, at a capacity of 650 tons per day, the NEOM project will commence hydrogen production in 2026, which will be used by green steel and cement industries, for the city to run at 100% renewable energy.

Based on steel end-use, the building & construction segment captured the largest revenue share of the market, with over 45.0% in 2022. Rising investment by emerging economies to modernize their infrastructure is expected to propel the demand for the product.

Based on region, the Middle East & Africa is expected to achieve a revenue growth rate of 4.3%, over the forecast period. This growth is primarily driven by the emergence of infrastructure projects in the Middle East, which in turn is boosting the demand for products in the region.

For More Details or Sample Copy please visit link @: Iron And Steel Market Report

Over 98% of the total iron ore transforms into pig iron, which is a crucial component in the production of steel. Finished steel products are used in various industries, such as heavy industry, construction, automotive, and consumer goods. In heavy industry, steel is a strong material that can handle heavy weights and tough conditions. It provides stability and safety to heavy machinery, equipment, and infrastructure by maintaining their structural integrity. Thus, it is widely used in heavy industries such as shipbuilding, defense products manufacturing, and oil & gas.

Investment in the oil & gas industry is expected to drive the demand for steel over the forecast period. For instance, in April 2022, Cairn Oil & Gas, a Vedanta Group subsidiary, announced investing USD 700.0 million in oil & gas exploration projects in India. The company plans to invest in 100 exploratory wells, including the project in the Barmer region of Rajasthan, India.

Despite the rising penetration in various end-use industries, the product faces hindrances in the automotive industry. Electric vehicles prefer to use aluminum because of its lightweight and robust characteristics. This lightweight property helps reduce fuel consumption and lowers carbon emissions. As a result, aluminum is increasingly being used as a substitute for steel in electric vehicles, and this trend is expected to negatively affect the global market growth in the foreseeable future.

Region-wise, Asia Pacific is projected to undergo substantial revenue growth with a CAGR of 3.6% across the forecast period. This growth can be attributed to substantial investments in the region's construction and infrastructure sectors of developing economies. For instance, The Indonesian parliament approved the Capital City Bill in January 2022, paving the way for constructing a new capital city in the East Kalimantan province. The country has plans to invest USD 35 billion in the project, which is projected to be finalized by 2024.

IronAndSteel #SteelIndustry #Metallurgy #SteelProduction #SteelManufacturers #SteelMarketTrends #MetallurgicalProcesses #SteelDemand #SteelProducts #SteelTrade #ConstructionMaterials #EconomicProgress #MetalsMarket #MetalInnovation #GlobalInfrastructure #Manufacturing #IndustrialDevelopment #InfrastructureDevelopment #EconomicGrowth #GlobalCommerce

#Iron And Steel#Steel Industry#Metallurgy#Global Infrastructure#Steel Production#Construction Materials#Metals Market#Metal Innovation#Steel Manufacturers#Steel Market Trends#Metallurgical Processes#Steel Demand#Economic Growth#Global Commerce#Steel Products#Steel Trade

0 notes

Text

Analytics in the steel production value chain

This article highlights use cases of advanced analytics (i.e. machine learning, mathematical programming, and simulation) in the steel production value chain. Steel products play an important role in our daily life, ranging from real estate construction, agricultural equipment, automotive parts and frames, home appliances, and also e.g. aerospace structural components. From the iron ore extracted…

View On WordPress

0 notes

Text

Spectrometer for Steel Industries: Ensuring Precision in Nitrogen and Oxygen Analysis

Steel industries require highly accurate tools to ensure the quality and composition of their products. A spectrometer plays a critical role in this process by providing precise nitrogen analysis in steel and oxygen analysis in steel, which are essential for maintaining desired mechanical properties and preventing defects.

Importance of Nitrogen and Oxygen Analysis in Steel

Nitrogen Analysis in Steel: Nitrogen affects the hardness, strength, and corrosion resistance of steel. Spectrometers allow manufacturers to monitor and control nitrogen levels to achieve consistent quality.

Oxygen Analysis in Steel: Excess oxygen in steel can lead to porosity and reduced durability. Using a spectrometer ensures precise oxygen content measurements, avoiding defects and improving product reliability.

Benefits of Spectrometers for Steel Industries

Enhanced Quality Control: Spectrometers provide real-time data, ensuring each batch meets industry standards.

Cost Efficiency: Early detection of composition issues reduces material waste and rework.

Compliance with Standards: High-precision spectrometers help meet stringent steel industry regulations.

Applications in Steel Production

From raw material inspection to final product quality checks, spectrometers are used across multiple stages of production. They are particularly beneficial for advanced grades of steel used in construction, automotive, and aerospace industries.

Conclusion

For steel manufacturers, investing in high-quality spectrometers is essential for accurate nitrogen and oxygen analysis. This ensures superior product quality, enhances customer trust, and optimizes production efficiency.

By leveraging advanced spectrometers, steel industries can stay ahead in a competitive market while maintaining top-notch quality control. Explore Metal Power's cutting-edge spectrometers today to elevate your steel production standards. Contact us now for a tailored solution!

#steel industry#qualitycontrol#NitrogenAnalysis#OxygenAnalysis#steelmanufacturing#metalpower#steelquality#steel production#metalanalysis

0 notes

Text

Since the early stages of Steel Manufacture, the steel factory sector has advanced significantly. Modern steel factories use a variety of cutting-edge technologies and eco-friendly procedures to mass-produce steel goods of the highest quality.

#Steel factory#steel manufacturing#steel manufacturers#steel producers and suppliers#steel production

1 note

·

View note

Text

I simply think they should be allowed to do whatever they want 😌

#worlds beyond number#wbn pod#suvirin kedberiket#steel wbn#did I do this instead of anything productive today? yes. and I am valid for it.#I really did not intend to sit down and do proper art pieces but here we are. it's fine. I'm fine.#anyway. FAVES. BELOVEDS. they are so great. geas? badass. idgaf they can do whatever they want!

270 notes

·

View notes

Text

Steel mill

“Koninklijke Hoogovens at IJmuiden, Holland” - via Wikimedia Commons

#wikipedia#wikipedia pictures#wikimedia commons#industry#industrial products#industrial production#steel#steel mill#industrial plant#manufacturing

118 notes

·

View notes